Automatic Flushing Strainer-Type Filters and Disc Filters for Microirrigation

Nov 22, 2016

General construction requirements and test methods for automatic flushing strainer-type filters and disc filters intended for operation in agricultural irrigation systems are shown in this article.

Terms and definitions

- Automatic flushing filter

Filter in which both the initiation and the termination of discrete flushing cycles are activated automatically.

- Duration of automatic flushing cycle

Period of time during which water and clogging material are flushed out.

- Flushing control mechanism

Mechanism which initiates and terminates the flushing action of a filter.

- Flushing valve

Valve through which flushing water is discharged from a filter.

- Minimum working pressure

Lowest pressure immediately upstream from a filter that is recommended by the manufacturer to ensure proper operation.

- Minimum filtering pressuree

Lowest working pressure immediately upstream from a filter, declared by the manufacturer, which ensures the proper functioning of a filter while in the filtering mode.

- Minimum flushing pressure

Lowest working pressure immediately upstream from a filter, declared by the manufacturer, which ensures proper flushing while in the flushing mode

- Prefiltration element

Part of a filter intended to protect the filter element and cleaning mechanism by collecting especially large particles of the clogging material prior to their reaching the main filter element.

- Protective mechanis

Mechanism that prevents repeated flushings of a filter caused either by mechanical failure in the flushing control mechanism or by some other fault.

- Volume of flushing water

Volume of water flushed from a filter during one flushing cycle.

Marking

Each filter shall bear all the markings as the following:

- Marking of filter housing

The marking of the filter housing shall include:

- The name of manufacturer and/or registered trademark,

- The model identification,

- The nominal size,

- The nominal pressure,

- An arrow indicating the direction of water flow,

- The aperture size (optional marking, applicable when a filter is supplied with the filter element already assembled).

The aperture size may be marked on an adhesive label affixed to the filter housing in a prominent position.

- Marking of filter element

The marking of the filter element shall include:

- The name of manufacturer and/or registered trademark

- The aperture size.

The aperture size may be indicated by a marking such as a specific colour that is defined in the Manufacturer's catalogue.

-

A calibrated permanent scale which shows the individual setting positions, where these exist, for the various options of adjustment of the automatic flushing cycle.

General requirements

Design and construction requirements

Mandatory requirements

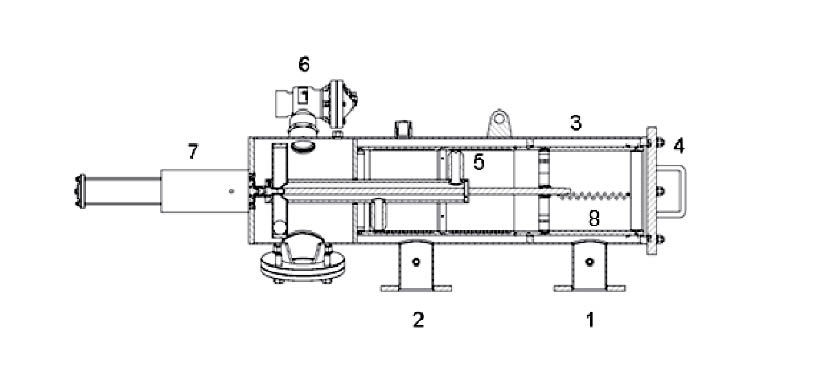

Models of typical automatic flushing filters are shown in Figure 1 and Figure 2.

Key

- inlet,

- outlet,

- filter housing,

- filter housing cover,

- filter element,

- flushing valve,

- flushing control mechanism,

- prefilter.

Figure 1 — Typical structure of an automatic flushing strainer-type filter

Key

- inlet,

- outlet,

- filter housing,

- disc elements.

Figure 2 — Typical structure of an automatic flushing disc filter

The construction of an automatic self-cleaning filter shall comply with the following requirements.

- The flushing control system shall be a part of the filter assembly and shall be supplied by the manufacturer together with the filter, or shall be a part produced by the filter manufacturer and supplied according to special demand of the customer. Alternatively, the flushing control system may be manufactured by a third party, provided that it is approved by the filter manufacturer and is included in the information supplied by the manufacturer.

- The construction of the filter shall allow manual actuation of automatic flushing in the event of failure of the automatic flushing control mechanism.

- The flushing control mechanism shall allow manual flushing at any time, irrespective of the conditions that apply to automatic flushing.

- The construction of the filter housing shall permit dismantling for maintenance (or for cleaning, if the filter is also designed for manual cleaning).

- The coordination of the flushing operation and the opening of the flushing valve shall prevent water flowing out of the flushing valve unless the filter is being cleaned. During flushing, it shall be open for at least one full flushing operation.

- The initiation and termination of flushing may be activated by pressure differential, by duration of filtration, by volume of water filtered, by another physical quantity or by a combination of these.

- When a prefiltration element exists, the maximum pressure drop across it shall be less than the safe maximum pressure drop of the filter assembly.

Optional features

In addition, the following construction features are recommended.

- The filter may be fitted with a device that enables adjustment of the preset value of the flushing control mechanism for initiation of the flushing cycle, for controlling the duration and termination of the flushing cycle.

- The filter may be equipped with a protective mechanism that prevents repeated flushings (see protective mechanism).

- All hydraulically operated accessories of the filter should be operated using filtered water, with the exception of the inlet pressure signal which may come from non-filtered water.

- The design of a prefiltration element, its filtering area, the size of water passages and their shape should be appropriate for the water quality for which the filter is intended.

NOTE 1 The prefiltration element is an optional component.

- The prefiltration element should be an integral part of the filter while being tested according to performance tests and performance tests of microirrigation filters after long term simulated use. (This element is not intended to be tested separately.)

NOTE 2 The prefiltration element is not automatically flushed.