Test Procedure for Filtration Grade of Microirrigation Filter

Nov 22, 2016

Microirrigation filters are import to agricultural irrigation systems, while the filtration grade of a filters is an important parameter that can assist to the utility of a filter.

Verification of filtration grade of a filter is intended to be used for verifying the filter manufacturer's declaration about the filtration grade of a specific filter. And the test method may also be used by a filter manufacturer to determine the filtration grade.

This test method uses a Clogging Capacity Meter (CCM) device to compare the filtration grade of the filter under test against the filtration grade of a test filtration screen.

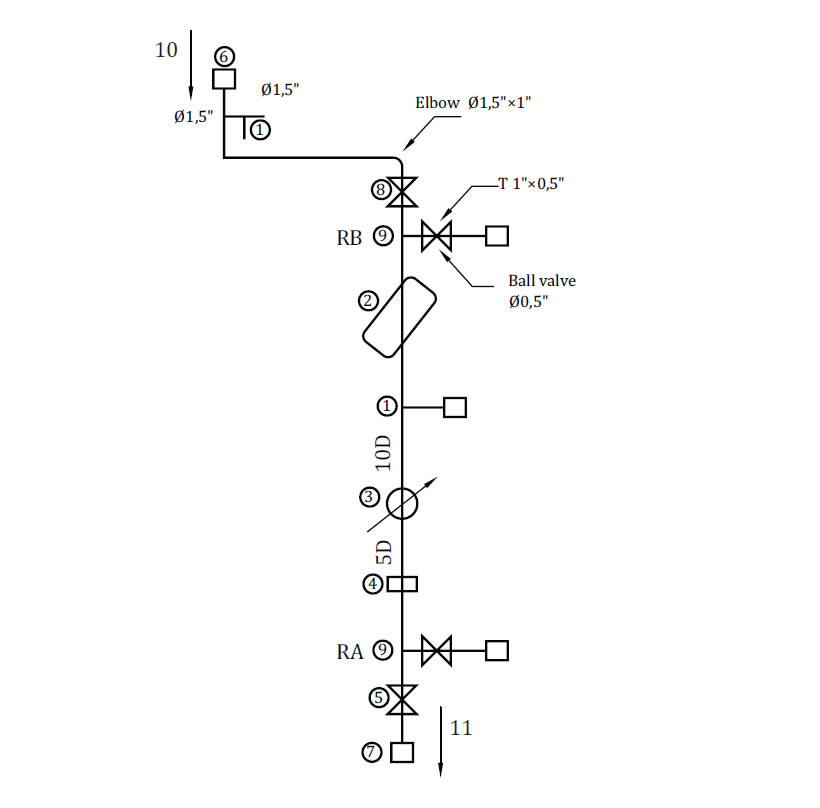

The Test system layout for Verification of filtration grade

Prepare the test system as per Figure 1.

Key

- pressure point – data logger;

- filter to be tested Φ1”;

- water meter Φ1”;

- flow regulator Φ1”;

- pressure reg. valve Φ1”;

- connection union P.E. Φ32;

- connection union P.E. Φ32;

- ball valve Φ1”;

- water checkpoint – CCM;

- water inlet;

- water outlet.

Figure 1 — Test system layout

Test procedure for Verification of filtration grade

- Adjust system inlet pressure to 4.0 bar, while water flow to the CCM units is blocked.

- Allow water to flow through the test system. Adjust the flow rate through the tested filter to the mid-point of the flow rate range declared by the filter manufacturer. Then adjust the pressure at the system inlet to between 3.0 bar and 4.0 bar.

- Record the pressure upstream and downstream of the filter and calculate the pressure loss across the clean filter.

- top the water flow in the system. Replace the filter medium with a new, unused medium of the same type and characteristics.

- Resume water flow in the system and open the valves to both CCM units.

- Continuously monitor the increase in pressure loss across the tested filter and across each CCM unit.

- Record the time required to reach a pressure loss of 0.5 bar in the upstream CCM (tup) and in the downstream CCM (tdown). Calculate and take note of the tdown/tup ratio.

- Replace the screens at both CCMs.

- If the pressure loss across the test filter exceeds the pressure loss recorded in the clean state by 0.5 bar (see 3. above), abort the test.

- Repeat 5 to 9 nine more times, then terminate the test.

- Calculate the average of all recorded tdown/tup ratios. If the result is equal to or greater than five, the filtration grade declared by the manufacturer is correct.

NOTE: Consider the discontinuation of the test if a pressure loss of 0.5 bar is achieved in less than 30 s and if a pressure loss of 0.5 bar in the upstream CCM is not achieved within 60 min.

About the terminology in this article, please refer to Filters Filtration Grade - Verification and Determination