GWM-01: Round wire galvanized wire mesh.

Galvanization, a common seen and widely used surface treatment, is widely used for carbon steel material to improve corrosion and rust resistance performance. It has electric galvanization and hot dipped galvanization types for choice.

Galvanized wire mesh adopts galvanized steel wires to be woven into pieces, sheets or rolls. And then they will be cut into different shapes to suit different applications.

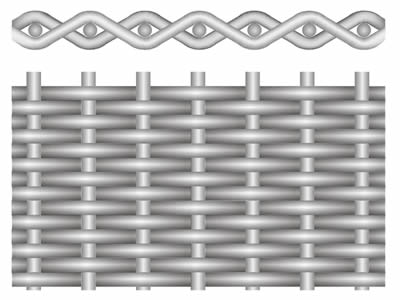

GWM-01: Round wire galvanized wire mesh.

GWM-02: Flat wire galvanized wire mesh.

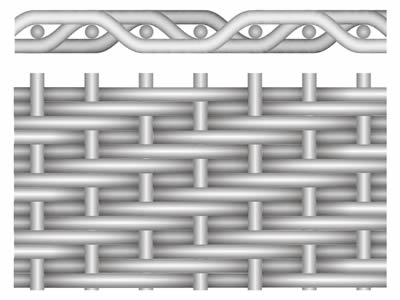

GWM-03: Plain weave galvanized wire mesh.

GWM-04: Twill weave galvanized wire mesh.

GWM-05: Plain dutch weave galvanized wire mesh.

GWM-06: Twill dutch weave galvanized wire mesh.

| Item | Mesh | Wire Diameter (mm) | Opening (mm) | Weight (kg/m2) |

|---|---|---|---|---|

| GPWS-01 | 1 | 2 | 23.4 | 2.0 |

| GPWS-02 | 2 | 1.5 | 11.2 | 2.25 |

| GPWS-03 | 3 | 1.0 | 7.466 | 1.5 |

| GPWS-04 | 4 | 0.9 | 5.45 | 1.62 |

| GPWS-05 | 5 | 0.8 | 4.28 | 1.6 |

| GPWS-06 | 6 | 0.7 | 3.53 | 1.47 |

| GPWS-07 | 7 | 0.6 | 3.02 | 1.26 |

| GPWS-08 | 8 | 0.5 | 2.675 | 1.0 |

| GPWS-09 | 9 | 0.5 | 2.322 | 1.125 |

| GPWS-10 | 10 | 0.8 | 1.74 | 3.2 |

| GPWS-11 | 11 | 0.7 | 1.609 | 2.695 |

| GPWS-12 | 12 | 0.6 | 1.516 | 2.16 |

| GPWS-13 | 13 | 0.5 | 1.453 | 1.625 |

| GPWS-14 | 14 | 0.4 | 1.414 | 1.12 |

| GPWS-15 | 15 | 0.4 | 1.293 | 1.2 |

| GPWS-16 | 16 | 0.35 | 1.237 | 0.98 |

| GPWS-17 | 17 | 0.35 | 1.144 | 1.041 |

| GPWS-18 | 18 | 0.35 | 1.061 | 1.10 |

| GPWS-19 | 19 | 0.35 | 0.986 | 1.16 |

| GPWS-20 | 20 | 0.4 | 0.97 | 0.97 |

| GPWS-21 | 21 | 0.3 | 0.909 | 0.945 |

| GPWS-22 | 22 | 0.3 | 0.854 | 0.99 |

| GPWS-23 | 23 | 0.25 | 0.854 | 0.718 |

| GPWS-24 | 24 | 0.25 | 0.858 | 0.48 |

| GPWS-25 | 25 | 0.2 | 0.816 | 0.50 |

| GPWS-26 | 26 | 0.2 | 0.076 | 0.52 |

| GPWS-27 | 27 | 0.2 | 0.740 | 0.54 |

| GPWS-28 | 28 | 0.3 | 0.607 | 1.26 |

| GPWS-29 | 29 | 0.3 | 0.575 | 1.30 |

| GPWS-30 | 30 | 0.3 | 0.546 | 1.35 |

| GPWS-31 | 40 | 0.25 | 0.385 | 1.25 |

| GPWS-32 | 50 | 0.2 | 0.308 | 1.0 |

| GPWS-33 | 60 | 0.15 | 0.273 | 0.675 |

| GPWS-34 | 70 | 0.14 | 0.222 | 0.686 |

| GPWS-35 | 80 | 0.12 | 0.197 | 0.576 |

| GPWS-36 | 90 | 0.11 | 0.172 | 0.544 |

| GPWS-37 | 100 | 0.10 | 0.154 | 0.50 |

| GPWS-38 | 120 | 0.08 | 0.131 | 0.384 |

| GPWS-39 | 150 | 0.07 | 0.099 | 0.367 |

| GPWS-40 | 380 | 0.02 | 0.046 | 0.076 |

| GPWS-41 | 400 | 0.018 | 0.0455 | 0.0648 |

| Items | Mesh | Wire Diameter (mm) | Mesh Aperture (mm) |

|---|---|---|---|

| GTWS-01 | 250 × 250 | 0.040 | 0.063 |

| GTWS-02 | 300 × 300 | 0.040 | 0.044 |

| GTWS-03 | 325 × 325 | 0.035 | 0.043 |

| GTWS-04 | 350 × 350 | 0.030 | 0.042 |

| GTWS-05 | 400 × 400 | 0.030 | 0.033 |

| GTWS-06 | 450 × 450 | 0.028 | 0.028 |

| GTWS-07 | 500 × 500 | 0.025 | 0.026 |

| Item | Mesh Count | Particle Retention (inches) | Thickness (inches) | Weight (lbs./sq.ft.) |

|---|---|---|---|---|

| GODS-01 | 10 × 52 | 0.0128 | 0.059 | 1.03 |

| GODS-02 | 12 × 64 | 0.0116 | 0.048 | 0.76 |

| GODS-03 | 14 × 88 | 0.0096 | 0.037 | 0.69 |

| GODS-04 | 24 × 110 | 0.0054 | 0.03 | 0.52 |

| GODS-05 | 30 × 150 | 0.0042 | 0.021 | 0.37 |

| GODS-06 | 40 × 200 | 0.0033 | 0.016 | 0.27 |

| GODS-07 | 30 × 150 | 0.0032 | 0.02 | 0.38 |

| GODS-08 | 50 × 250 | 0.0025 | 0.012 | 0.22 |

| Item | Weft × Warp (inch) | Aperture Size (μm) | Available Area (%) | Thickness (mm) |

|---|---|---|---|---|

| GTDS-01 | 20 × 270 | 119 | 17.6 | 0.65 |

| GTDS-02 | 20 × 200 | 118 | 12.1 | 0.915 |

| GTDS-03 | 24 × 300 | 110 | 19.6 | 0.64 |

| GTDS-04 | 20 × 150 | 101 | 7.5 | 1.16 |

| GTDS-05 | 30 × 340 | 89 | 17.9 | 0.60 |

| GTDS-06 | 30 × 270 | 77 | 11.2 | 0.68 |

| GTDS-07 | 40 × 540 | 70 | 23.5 | 0.38 |

| GTDS-08 | 40 × 430 | 63 | 15.4 | 0.43 |

| GTDS-09 | 50 × 600 | 51 | 17.2 | 0.305 |

| GTDS-10 | 50 × 500 | 47 | 12 | 0.364 |

| GTDS-11 | 65 × 600 | 36 | 12 | 0.32 |

| GTDS-12 | 70 × 600 | 31 | 10.1 | 0.32 |

| GTDS-13 | 78 × 760 | 31 | 13.5 | 0.254 |

| GTDS-14 | 78 × 680 | 29 | 10.3 | 0.272 |

| GTDS-15 | 80 × 680 | 28 | 9.8 | 0.272 |

| GTDS-16 | 90 × 850 | 26 | 12.7 | 0.226 |

| GTDS-17 | 90 × 760 | 24 | 9.6 | 0.242 |

| GTDS-18 | 100 × 850 | 22 | 10 | 0.226 |

| GTDS-19 | 130 × 1500 | 21 | 18.6 | 0.135 |

| GTDS-20 | 100 × 760 | 20 | 7.4 | 0.242 |

| GTDS-21 | 130 × 1200 | 18 | 12 | 0.161 |

| GTDS-22 | 130 × 1100 | 17 | 9.4 | 0.171 |

| GTDS-23 | 150 × 1400 | 15 | 11.4 | 0.143 |

| GTDS-24 | 160 × 1500 | 15 | 12.4 | 0.135 |

| GTDS-25 | 165 × 1500 | 14 | 11.4 | 0.135 |

| GTDS-26 | 174 × 1700 | 13 | 12.9 | 0.127 |

| GTDS-27 | 165 × 1400 | 13 | 8.8 | 0.143 |

| GTDS-28 | 174 × 1400 | 11 | 7.4 | 0.143 |

| GTDS-29 | 203 × 1600 | 10 | 9.3 | 0.114 |

GWM-07: Galvanized wire mesh filter disc.

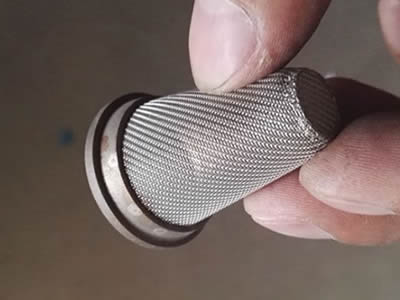

GWM-08: Mini filter tube.

GWM-09: Galvanized wire mesh filter tube.

GWM-10: Galvanized wire mesh twill weave filter element.

GWM-11: Galvanized wire mesh pleated filter cartridge.

GWM-12: Galvanized wire mesh plain weave filter element.

GWM-13: Galvanized wire mesh folded window screen.

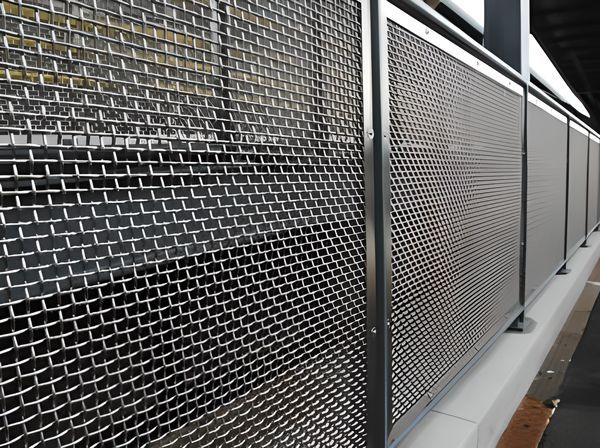

GWM-14: Galvanized wire mesh partition.