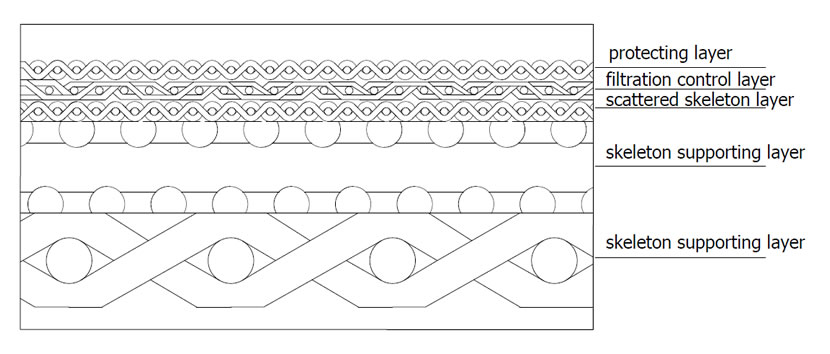

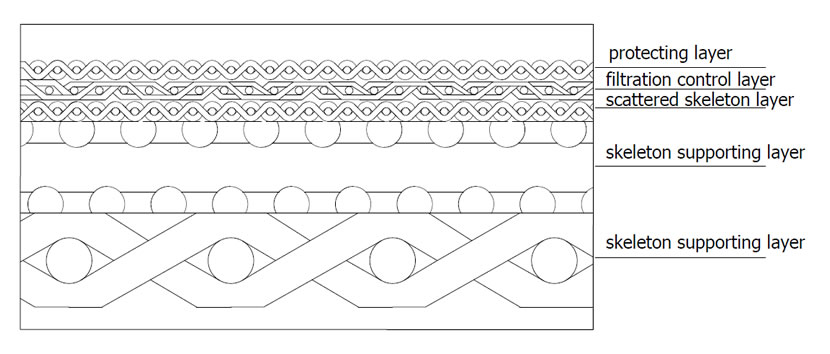

The structure of sintered filter disc: protecting layer, filtration control layer, scattered skeleton layer, skeleton supporting layer.

Sintered filter disc, also known as sintered wire mesh filter disc, is a new filter disc product. Sintered filter disc is the combination of multi-layer filter disc. Such as woven filter disc and perforated filter disc. Generally, it has five layers and the its structure includes protecting layer, filtration control layer, scattered skeleton layer, skeleton supporting layer. According to its material, it can be classified into stainless steel sintered filter disc, galvanized sintered filter disc, copper sintered filter disc and bronze sintered filter disc. Among these specific products, stainless steel sintered filter disc is the most popular. Stainless steel sintered filter disc, is made of stainless steel mesh cut by laser cutting machine with high precision in high vacuum furnace.

The structure of sintered filter disc: protecting layer, filtration control layer, scattered skeleton layer, skeleton supporting layer.

SFD-1: Sintered filter disc can be produced with perforated type and woven type.

SFD-2: Stainless steel sintered filter disc.

SFD-3: The material of sintered filter disc: iron, stainless steel, brass, etc.

SFD-4: Brass sintered filter disc features accurate filtration precision.

| Item | Mesh counts | Wire Diameter (mm) | Aperture (mm) |

|---|---|---|---|

| SSSFD01 | 8 - 28 | 0.3 - 1 | 0.8 - 2.66 |

| SSSFD02 | 35 | 0.17 | 0.56 |

| SSSFD03 | 40 | 0.23 | 0.40 |

| SSSFD04 | 50 | 0.20 | 0.31 |

| SSSFD05 | 60 | 0.15 | 0.27 |

| SSSFD06 | 70 | 0.12 | 0.24 |

| SSSFD07 | 80 | 0.13 | 0.19 |

| SSSFD08 | 90 | 0.12 | 0.16 |

| SSSFD09 | 100 | 0.10 | 0.15 |

| SSSFD10 | 120 | 0.09 | 0.12 |

| SSSFD11 | 150 | 0.063 | 0.11 |

| SSSFD12 | 180 | 0.053 | 0.09 |

| SSSFD13 | 200 | 0.053 | 0.07 |

| SSSFD14 | 220 | 0.05 | 0.065 |

| SSSFD15 | 250 | 0.04 | 0.062 |

SFD-5: Perforated sintered filter disc with accurate and steady filtration rate.

SFD-6: Woven sintered filter disc with high dirt holding capacity.

Sintered filter disc with accurate filtering efficiency and long working life, the same as stainless steel filter disc and copper filter disc, is the ideal filtering instrument for filtering and screening. And it is widely applied in electronic industry, petroleum industry, environmental protection and sewage treatment, pharmaceutical industry, etc.