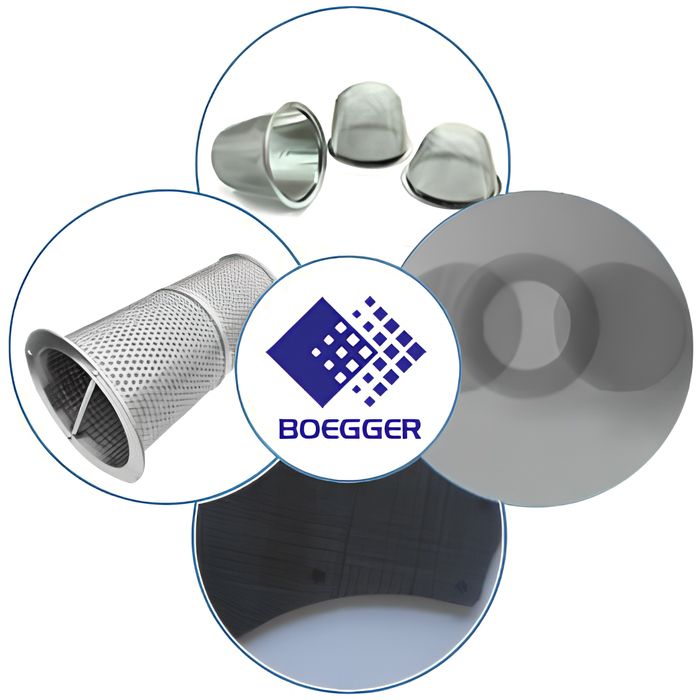

Boegger Industech Limited is a professional company specialized in the production of filter disc. Since 2000, Boegger has been committed to produce high quality filter disc. Now Boegger has become one of the leading manufactures of filter disc. The operating principle of Boegger filter disc is removing unwanted contaminants from fluid, air or solid. Thus you can acquire what you want without impurities. So when you meet this kind of problem, Boegger filter disc is your best choice!

Metal filter disc features better performance in damper environment or where paper filter discs couldn't supply sufficient rigidity and strength. It also features outstanding durability and suitable ability. Therefore it not only can withstand temperature range in excess of 500 F and high pressure but also can be manufactured by spot welding and perforating. What's more, filter discs can be designed to be compatible with most caustic fluids and they are cleanable and reusable. Therefore, compared with paper and cloth filter discs, metal filter discs can offer a long service life.

Metal filter discs are mainly used in distillation, absorption, evaporation and filtration process in rubber, plastic industry, sewage treatment, petroleum, chemical industry, pharmacy, metallurgy, machinery, ships, vehicle industry, food making and other industries. In addition, filter discs may be made into microirrigation disc filters for microirrigation equipment intended for operation in agricultural irrigation systems.

Air conditioner, air regulator components, filtration of corrosive gases, etc.

Ceramics polluted water cleaning, beverage, disposal of sewage water, filtration of corrosive liquids, etc.

Glass, coal, food processing industry, etc.

Petroleum, oil refining, hydraulic oil, edible oil filter, etc.

Textile industry, insulation industry, automotive industry, chemical industry, metallurgy, medicine making, etc.

If you are interested in our filter disc series or cylinder filter series, please provide: filter material, weaving type, filter shape, layers, edge processing methods, packing dimension and quantity. In addition, if you want to know more information about our products and services, please browse our website or mail at sales@filter-disc.com.

A test method for the verification of filtration grade of filters intended for operation in agricultural irrigation systems. also to determine the filtration grade.

Filters are import to agricultural irrigation systems, test system layout and test procedure for verification of filtration grade of microirrigation filters here.

General construction requirements and test methods for strainer filters and disc filters intended for operation in agricultural irrigation systems.